Recent years have seen the growth of sub-contracting, piece work, self-employment, daywork, zero-hour contracts, minimum wages and the use of agencies in the never-ending attempt by capital to reduce the cost of labour. This is an account of the use of sub-contracting in the mining industry in the Forest of Dean 1922 – 1938. It examines the impacts of the system on workforce cohesion and solidarity as well as the extent to which it succeeded in increasing the rate of exploitation of the workforce to the benefit of the employers and how it was eventually brought to end by the miners themselves.

Introduction

One of the consequences of investment by mining companies in deep mining in the nineteenth century was a large increase in the number of miners. However, there was a common perception among many historians that miners had now become wage labourers or ‘archetypical proletarians’. By this, they meant miners had turned into a uniform class of industrial wage earners with identical interests and status who, possessing neither capital nor production means, earned their living by selling their labour with little or no control over the day to day conditions of work.

Adam Smith, in the Wealth of Nations, offered a striking contrast between the `independent workman’, on the one side, and ‘the collier’ on the other. The former is represented by the figure of the weaver or the shoemaker, who may still have a property in loom or last, linen or leather. The latter owns nothing but his ability to work, an ability which is seen as being perfectly indistinguishable from that of the ‘common labourer’. If the coal miner is more highly paid, it is not because he has any skill; but is entirely due to the greater hardship, disagreeableness and inconstancy of employment which characterises his work.[ 1 ]

Miners were perceived as living in occupationally homogeneous communities, sharing common work experiences and pursuing a common interest. As a result, miners were believed to have developed strong solidarity in their conflicts with their employers who struggled to come up with strategies to undermine their demands for improved working conditions.

In 1978, Chris Fisher, Royden Harrison and others from mining backgrounds challenged this view in their classic study of the nineteenth-century collier in the book the Independent Collier, The Coal Miner as an Archetypal Proletariat Reconsidered in which they explore, amongst other things, the butty or contract system of working in British coalfields in the nineteenth century. [ 2 ] The buttyman was a self-employed contractor who worked for a colliery owner hewing coal and other tasks and employed a small team of day men and boys.

Further studies have shown that the contact system became a significant feature of the British coal mining industry in the twentieth century. Barry Johnson’s study of in the Nottingham coalfield (Who Dips in the Tin? The Butty System in the Nottinghamshire Coalfield) and Robert Goffee’s study of the Kent coalfield (Incorporation and Conflict: A Case Study of Subcontracting in the Coal Industry) illustrate how the hierarchy and inequalities created by the contract system of working impacted on trade unionism by fragmenting the labour force and undermining solidarity.[ 3 ]

On the other hand, Dave Douglass’ study of the Durham Pitman has revealed how a unique and more democratic form of organisation within the contract system in the Durham coalfield created a strong sense of group solidarity and equality within small working groups.[ 4 ]

These accounts demonstrate that nationally there were not just one contract system but many different types of contract systems depending on local custom and practice. This article will attempt to build on these studies by an investigation into the contract system of working in the Forest of Dean coalfield from 1921-1938 and will explore the role of Forest of Dean miners as skilled artisans and small working masters.

In the Forest of Dean, the butty system operated in most of the deep mines from the early nineteenth century onwards until it was finally abolished at Eastern United in 1938. The first part of this paper will provide an outline of how the butty system operated in the Forest of Dean coalfield in the 1920s and 1930s.[ 5 ] The discussion will be illustrated by oral history statements in Forest dialect from a cross-section of Forest miners to reflect a range of views on the topic which reveal common features but also highlight complexity and contradictions. The second section will detail the events surrounding the demise of the butty system at Eastern United colliery in 1938.

The Butty System

At Wednesday’s meeting of the Miners Conference, now sitting in Nottingham, the butty system came under review and was universally condemned. One of the speakers characterised it as the worst evil under which the miner suffered, and another as the root of most of the miners’ grievances. The views of the Conference on the subject are to be embodied in their petition to parliament. Gloucester Journal 17 November 1866 .

There were about 6000 miners working the deep pits owned by the large mining companies in the Forest of Dean in the 1920s. However, a small number of independent free miners worked small pits, usually drift mines, operated by just a few men.[ 6 ] Free mining rights had been claimed from ‘time immemorial’ by any son of a free miner born in the Forest of Dean who had worked a year and a day in a Forest pit. This right allowed any free miner to open a pit anywhere in the statutory Forest of Dean, provided he paid royalties to the Crown, the owner of the land.[ 7 ]

The early nineteenth century saw the penetration of, and transformation of, the old free mining coal industry by capitalists from beyond the borders of the Forest. In the years between 1790 and 1830 the mining industry in the Forest of Dean had passed, in the main, from the hands of a relatively large group of working proprietors of small scale co-operative pits into those of a small group of men, mostly outside capitalists, who brought with them the steam engine, deep mining, railroads and iron furnaces. The rights of free miners were curtailed and, as a result, most of the inhabitants of the Forest were now dependent on the wages they earned working in the new deep pits owned by the capitalists.

Free mining continued but by the 1920s, the output of the free mines was small compared to the deep pits, although in terms of culture and Forest identity it was very important. There were about 670 men working about forty small pits in 1918, many of them owned by free miners. In the Independent Collier, Chris Fisher argues that the development of the butty system in the nineteenth century in the Forest had its roots its tradition of free mining in which colliers sought to retain their independence as small working masters and skilled artisans. [ 8 ] Fisher develops this argument in his book Custom, Work and Market Capitalism, The Forest of Dean Colliers, 1788-1888.[ 9 ]

How the Butty System Worked

In the larger deep pits, the buttyman was allocated a ‘stall’ or section of seam by the colliery manager and employed a number of boys and men to help him extract the coal. The stall was a rectangular area of coal to be extracted which the buttyman regarded as his ‘place’. Sometimes this ‘place’ was shared with one or two partners or butties. The buttyman was paid a fee by the colliery owner for each ton of coal sent to the surface. In the Forest of Dean, the rate the buttyman was paid per ton of coal extracted was negotiated with the colliery owner locally by the individual buttyman, with the support of the Forest of Dean Miners Association (FDMA), the trade union representing the Forest miners. The rate was dependent on the conditions at the face, the width and quality of the seam, systems of working and other factors such as faulting, the condition of the roof or floor, water, etc.[ 10 ]

Most other tasks in the pits were carried out by men or boys employed directly by the owners. They were paid a day rate and were often referred to as the company men. These included the banksmen, enginemen, blacksmiths, masons, carpenters, pumpsmen, deputies, overmen and surface workers.[ 11 ]

Also included were men and boys involved with the haulage of coal, maintenance of haulage roads, clearing roof falls, and attending to ventilation.[ 12 ] In some circumstances, such as when the contract rate for a seam had yet to be agreed, the buttymen would work for an agreed standard day rate. However, the employers insisted on tonnage rates whenever possible, as they believed the buttymen would not work as hard without an incentive.

The contract system was widespread throughout British coalfields during the 1920s and 1930s and most hewing teams, timber men and those involved with opening up roadways were normally paid piece rates.[ 13 ] The differences between districts on how the earnings were shared out within the teams working on the contract depended on local custom and practice. There was a spectrum of systems, some more egalitarian than others. In some districts, such as the Midlands, a single contractor might employ a large number of day men working a whole seam and he was viewed by the rest of the miners as very much part of the management hierarchy.[ 14 ] The system was imported from the Midlands into the Kent coalfield in the 1920s and survived until the late 1930s.[ 15 ]

Little Buttymen

In some other districts, the earnings were shared out equally between all the men in the team such as the marras system in Durham.[ 16 ] Whereas the puffler system in Yorkshire was similar to the butty system but by the 1940s the leader of the working group was paid an extra allowance by the colliery company rather than excess earnings. [ 17 ] Whilst in other areas a pair of buttymen might employ just one boy. It is unlikely that, even in the most equitable systems, the boys were paid as much as the men and it is possible there were differentials depending on age and experience. In the Forest of Dean, Chris Fisher characterised the Forest of Dean contractors as ‘little buttymen’ because they only employed a small number of men and boys.[ 18 ]

The term butty system must, therefore, be used with considerable caution as its meaning varied considerably from district to district, pit to pit and seam to seam and changed over time. In 1870, a government commission investigated if the truck system, was still operating in the British coalfields.[ 19 ] During the investigation, it became clear that in some cases in the Forest to Dean, butties and mine owners were paying their men using credit notes for shops and in pubs, some of which were owned by themselves or family members. Although the commission concluded that in the Forest, the system of payment was not being abused by the employers, despite this it was clear buttymen were paying their men in pubs.[ 20 ] In 1886, Thomas Hale a butty mining ochre for the Crawshays wrote in his diary:

When I was a lad working in the coal pits, the butties used to take us to some public house and cause us to spend some of our money that one had worked very hard for.[ 21 ]

In addition, the newspaper reports revealed that in some pits the butties at Lightmoor and Trafalgar were employing up to 70 men. This means that in some cases the buttymen were in control of whole seams or sections of the mine as they were in Nottingham and Derbyshire. However, in terms of the social relations, there was a significant difference between these contractors and the little buttymen employing one or two labourers.

In the Forest of Dean, by the 1920s, most teams consisted of a butty or a pair of butties with one or two day men and a boy, although some teams were larger and the system varied from pit to pit. By now, it was unlikely the buttymen used sticks and were much more likely to be directly involved with hewing themselves. However, at Eastern United colliery, in the 1920s, the teams varied from about four men up to about nine men.[ 22 ] Alan Marfell, who worked at Trafalgar Colliery in the early 1920s, remembers:

Will Reed and Frank Arkell were the two buttymen and had several other men working for them, who were paid a daily wage. Any money earned over and above that was shared by the two buttymen. This system was used in all the house-coal collieries at the time.[ 23 ]

As a result, the butty system created divisions within the workforce which impacted on the development of the FDMA and its relationship with the colliery owners. The divisions were not only between the buttymen and their daymen but also between the buttymen themselves as they competed for the best workplaces or stalls. This could lead to victimisation or favouritism because some stalls were more difficult to work than others because of water, faulting, soft roofs, etc. At the same time, the buttymen were aware that an experienced day man could always step in to take their place during a dispute with the owners.

In other districts such as Durham, these problems were overcome by the cavilling system where places were allocated afresh by drawing lots every quarter.[ 24 ] In contrast, at Lightmoor, a Forest house coal colliery, a buttyman could work the same section of a seam for many years and the places or roads were often named after him. Harry Barton whose father and grandfather were buttymen remembers working for his father at Lightmoor.

This road was nearly a mile long from the main road which we called ‘Barton’s Road’. My grandfather and father worked that road. The next road below was 30 yards on down, then there was another road which was called ‘Morse’s Road’, that meant, you were from Ruspidge. On a little bit further was ‘Woolford’s Road’.[ 25 ]

Most Forest buttymen identified with the principles of trade unionism and often were active members of the FDMA who supported them in their conflicts and negotiations with the colliery owners. In particular, it was important that the buttymen did not compete with each other for contacts or undermine each other by offering low contract rates. As a result, the piece work rates lists were usually agreed with the direct involvement of the FDMA representatives at the pit. In fact, up to the 1920s, the FDMA was effectively a buttyman’s union and the majority of disputes were to with the buttyman’s concerns such as tonnage rates, extra allowances for dead work, etc. In the early 1920s, the majority of the FDMA Executive committee were still buttymen or checkweighmen.

Checkweighmen

Coal hewed by the buttyman and his team was sent to the pit head in marked drams and then weighed by the employers’ weighmen and also by the FDMA checkweighman. The checkweighman was elected by the miners to verify the findings of the colliery owner’s weighman. Therefore, a checkweighman had to be someone whom the men trusted and he often became the FDMA representative at the pit and was often called upon to resolve disputes over tonnage.

One of the problems for the FDMA was that the checkweighmen were also accountable to the buttymen and as a result, this could result in divided loyalties in cases of disputes between the buttymen and their day men. This was a source of weakness within the FDMA and in the past, this weakness had been exploited by the colliery owners. As far back as the mid-nineteenth century, there was discontent in the Forest of Dean with a system which encouraged exploitation and division to the advantage of the colliery owners.[ 26 ]

Despite this, in the 1920s, the majority of men on FDMA Executive were checkweighmen. One example was Jesse Hodges (1880 – 1964) who was born in Nailbridge, near Cinderford. He started work in an iron mine as a boy and then moved to Crump Meadow colliery where he worked his way up to be a buttyman, employing his son, Jesse Hodges (Jnr), as a labourer and hodder. Jesse Hodges (Snr) was then elected to the post of checkweighman and represented Crump Meadow on the FDMA Executive during the lockouts of 1921 and 1926.

The 1921 Agreement

In March 1921, the government passed the war-time control of the collieries back to their owners who then announced a reduction of wages by about fifty per cent. The miners across the country refused to accept this and, as a result, were locked out. They were forced to return to work in July 1921, defeated and demoralised. An agreement reached between the Miners Federation of Great Britain and the colliery owners in July 1921 provided a new principle for the determination of earnings. The terms of the National Wages Agreement of 1921 laid the foundations for wage structures in the industry until the Second World War.[ 27 ]

The 1921 agreement provided for a minimum wage determined locally and based on earnings received in 1914 in that district for the different categories of day workers, giving a minimum wage for a hewer in the Forest of Dean in December 1921 of 7s 5d. This rate was considerably lower than in most other districts. Percentage additions were added to the minimum wage depending on the profitability of all the mines in the district, established by a joint audit each month.

The majority of the miners, including those employed by the buttymen or by the company, were paid day rates down to this guaranteed minimum plus the percentage. The buttymen were also paid the minimum day rate plus the percentage if their piece work earnings fell below this minimum. This could be the case if the team were working in abnormal places or difficult conditions where it was harder to get the coal, which was not unusual in the Forest of Dean coalfield.

However, the day wage for the craftsmen, general labourers surface workers was considerably lower than for the hewers. In December 1921, the minimum day rate for John Ballinger, an adult surface worker at Princess Royal colliery, was 4s 10d.[ 28 ] In 1922, at the age of 14, Percy Bassett started on the screens at New Fancy colliery and was paid 9d a day. He then worked as a hodder at 11d a day before being promoted to work on the pumps at 2s 6d a day.[ 29 ]

The 1921 agreement also linked the new piece work rates (base rates) to the wages paid in 1914. As in the case for the day rates, the piece work base rates diverged considerably between different areas, pits and coal seams, depending on local conditions and negotiations. New price lists were settled when new conditions arose or new seams or faces opened up.

Under the terms of the 1921 agreement, percentage additions were added to the base rates depending on the profitability of all the mines in the district. In January 1922 the day rate for a skilled hewer in the Forest was down to the minimum at 7s 5d. and along with Bristol, this was the lowest rate in the country. In the Forest of Dean, in the 1920s and 1930s, the profitability of the collieries was low or sometimes even zero and consequently so were the percentage additions.[ 30 ]

This meant that for periods many miners in the Forest, including at times the buttymen, were working for the statutory minimum day rates. Forest miner, Eric Warren, explained the system thus:

Two butty men would take the main headings and two butty men would take the stalls off the main heading. The butty men were paid so much for coal got out and so much per yard for rippin’ the roadways and they were responsible for payin’ the men. The minimum wage was seven and fivepence per day, less stoppages and the butty men would share out. If not enough coal was got, the company guaranteed the butty men seven and ninepence per day.[ 31 ]

In contrast, the rate for a skilled hewer in Nottinghamshire in January 1922 was 17s 4d per shift due to a higher minimum rate and percentage additions. However, by the middle of 1922, the wages in all districts except Nottinghamshire fell to their district minimums and in August 1922, the wage for a skilled hewer in Nottinghamshire was down to approximately 11s a shift.[ 32 ]

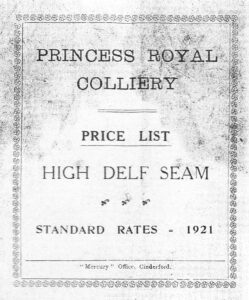

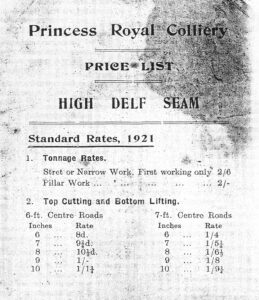

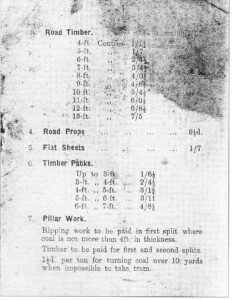

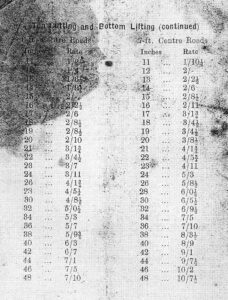

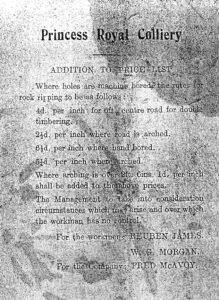

Price Lists

In the majority of pits, an agreement between the FDMA and colliery owners included a detailed price list which listed the tonnage rates for coal produced and a piecework rate for other jobs such as road ripping (paid by the yard), installing and repairing timberwork and associated work such as clearing dirt, which was not directly productive.[ 33 ]

The price lists were regularly reviewed by the colliery management usually by negotiation with the FDMA and the buttymen. These negotiations took place all the time and often on the spot. If the issue was not resolved the team could down tools leading to a strike involving the whole pit. This was the case in 1909 when six buttymen came out in a dispute over the cutting of a pillar of coal at Flour Mill colliery and when the owners sacked the buttymen, the rest of the 700 men also came out on strike in support. As a result, the owners threatened to close down the pit. The buttymen took the matter to court but lost and the strike was over within the month.[ 34 ]

Other tasks such as road ripping and timbering were carried out by individuals working on their own or in pairs but usually still on piece rates. These men were either employed directly by the colliery or by a buttyman as part of his team. At the time of the 1926 Lock Out, a Cinderford miner explained in a letter to the Gloucester Citizen how the butty system operated:

According to the agreement, every collier knows that there is what is known as a basic rate for cutting coal, timbering, etc. This varies according to the seam of coal worked, for instance: the ” Starkey ” vein of coal, which is from 12 inches to 14 inches thick, has the highest price per ton, namely 3s. 9d., plus percentage, which in any case would not be more than 7s. 6d. at the rate paid before the stoppage.

The basic rate paid for taking a road 10 feet wide by 7 feet high is 10s. per yard, plus of course 80 per cent according to the new terms in this seam. The roof to be taken down would be 5ft. 6in in thickness and 9ft. in width, and if any timber were required the price per pair would be 1s. 9d. plus, of course, percentage, and 2s. 6d. for partong caps, that is timber where two roads are separating.[ 35 ]

Bob Nailing

Since the buttymen were paid on piece rates and acted as supervisors, there was no need for micro-management of the teams working deep in the mine. In addition, the butties employed their day men, so the colliery owners had no employment obligations such as supervision, the hiring and firing of labourers and health and safety. However, the colliery owners were obliged to pay compensation in the cases of death injury and so there was no deterrent on the buttymen to take risks.

So, while the buttymen had a high degree of control over the work process, the day men were reduced to casual day wage workers subject to the whims of the market, the colliery owners and the buttymen themselves. In addition, in the 1920s and 1930s miners were periodically laid off with the rest getting only two or three days work a week. In periods when the trade was slack, there always was a temptation for the buttymen to take most of the work for themselves and the day men were the first to be laid off. In the Forest, this was called ‘bob nailing’. However, the depression in the coal trade lasted throughout the 1920s and 1930s and often the buttyman and his team could only work part time:

You had to listen for the hooter every night and every pit had its hooter and everybody knew their own pit’s sound of hooter. And if there was no work the next day, they would give loud blasts on the hooter for minutes on end – no work tomorrow … that was called a play day.[ 36 ]

In the 1930s unemployment in the Forest of Dean was sometimes over fifty per cent. Bream miners used to hang out by the hard luck tree waiting to see if there was work the next day. This is a poem by Harry Price:

Twas during the thirties,

When depression was rife,

Short time in the pits,

But accepted as life.A long walk to Lydney,

To sign on the dole;

Three times in a week

Destroying their souls.And back to the tree,

To sit on its roots.

With patches on knees,

Yes, holes in their boots.Perhaps they’d a tanner,

To put on a nag.

To relieve the monotony-

Then smoke the last fag.

If there was work, the buttymen was obliged to pay the minimum rate plus any percentage addition for each category of worker. The buttymen’s earnings were depended on the tonnage of coal extracted. The actual difference between the earnings of a skilled day rate hewer and a buttyman is difficult to ascertain but in the Forest of Dean in the 1920s and 1930s, both were often working for little above the minimum rates. One estimate for this period gives the buttymen receiving on average 5s to 10s more a week than the hewers he employed.[ 37 ] One of the factors affecting the earnings of the buttymen was the type of working system used and the number of men and boys in his team.

Systems of Work

The pillar and stall system was used on the thicker steam coal seams found at a deeper depth such as the Coleford High Delf vein. In this system, the stalls were about 3-5 yds wide and the seams up to about 2 yds in depth. Pillars of coal were left behind to support the roof as the seam moved forward and then usually removed at a later stage. The thickness of the seam gave sufficient height for the trams to be brought practically right up to the face where they could be loaded with coal and taken by the trammer to the main road.[ 38 ]

The buttymen often worked in a partnership of two or three men (butties) to cover two or three shifts in the same stall and with just one day man on each shift and usually a boy working as a trammer and labourer. Forest miner Len Biddington described the system:

There’d be three butty men, one for mornings, one for evenings and another for nights, for each stall and two men at a stall. The butty man would have a man he’d pay day wages, the butty men were paid on the coal and the yardage and all the overplus would be shared out between the dree butty men.[ 39 ]

The longwall system of working was used in the house coal collieries on the upper, thinner house coal seams. This system of extracting coal involved driving two advance tunnels or headings about 100 yds to 120 yds apart and extracting the coal from between the two headings. The width of the stalls or sections of the seam to be worked by each team was usually about 15 to 40 yds. Rubbish was thrown into the gob which was the empty waste area back behind the face, which was allowed to gradually collapse in a controlled manner as the face advanced.[ 40 ]

The thinness of the seams meant that hodders were employed to drag the coal out, under a roof which sometimes was only about 18 inches high, from the face along the small trolley or hod road to a larger road which ran parallel to the face. Alan Marfell described the technique at Trafalgar colliery in the 1920s.

Sometimes the seam was only eighteen inches high (or even less) to work under. You had to learn how to work under that height, how to lie out to use a pick, how to use a sledge for driving a wedge to bring the coal down after undercutting, and how to use a shovel to put your undercutting in the ‘gob’ behind you.[ 41 ]

The system usually required more day men including at least two hewers, hodders and possibly a trammer or filler on each shift, although in some instances two butties would work with one hodder. In 1922, J W F Rowe described the Forest of Dean longwall system in this way:

The stalls usually extend 15 to 20 yards each side of the ‘trolley’ road, or gateway leading back to the main road. In each stall, there are two, three, or four hewers, who do all the work at the face. When the coal is broken out, it is collected by a ‘hod boy’. The trolley road is often very low as it nears the face, and the hod boy may have to take his hod a considerable number of yards down the trolley road before emptying it into the trolley. When it is full the trolley is pushed by hand back to the main road, and then it is emptied into a tram or large truck, which is taken by horses to the shaft. The tram is loaded by a filler, and the hand-putting of the trolley may be done either by him or by the hod boy. The hod holds about two scuttles-full, the trolley about 8 to 10 hundredweights, and the tram anything from 20 to 30 hundredweights …. Two of the hewers or sometimes three, share equally, and employ other men at the face, together with the hod boy and, the filler, all on day rates.[ 42 ]

The buttymen and the hewers were regarded as the elite of the workforce but they worked in the most difficult and dangerous conditions and this was particularly so for those working the thin seams in the house coal pits. Life for the day wage hewer was hard. According to Jesse Hodges (Jnr) who worked for his father who was a buttyman:

You had to lie on your side, you dragged on your side in a way or on your belly, to get the coal out. I’ve seen men, “Mollie” Morris he was a great big man, he used to work in thirteen inches, he used to squeeze his stomach right in. He worked on his side and it was wet, water coming down all the time in that seam, and you dragged yourself in and you dragged yourself out and men worked in that. They lay on their sides to work, hauling the coal out. There was hardly any room to use your pick … And that’s how that was done. That’s what I said, we were animals. We were classed as animals and treated as such. They were bad old bosses in those days. They were the boss and you had to beg for bread.[ 43 ]

Fathers and Sons

In both systems, the degree of job control enjoyed by the buttyman was almost complete. The buttyman was autonomous in the organisation of his work tasks and responsible for all aspects of coal extraction with little external supervision. An inspection of inquest reports into deaths in Forest mines reveals that most buttymen were directly involved in the physical work on the coalface. Molly Curtis, born in 1912, remembers that her father who was a buttyman earned more than the daymen but complained about his responsibilities.

They used to have “places” and then they had to share out the money and dad used to say “Oh, ‘I hate it on a Friday when I can’t give those men as much as I feel they earned ‘…….Dad was the keeper of the place, you know it was his “place”. He had a lot of responsibilities, you know, and sometimes he used to say if he couldn’t get enough coal out, then he used to have to go back grovelling to the manager and they didn’t like grovelling.[ 44 ]

It was quite usual for young boys to start their mining career working for their fathers and often hewing teams were made up of fathers, brothers and sons. It was likely that many young skilled miners aspired to follow in the footsteps of their fathers to become their own working masters with their own stalls or section of seam to work. Harry Barton started work for his father just before World War One. After serving in the military he returned to the pit and later became an active member of the FDMA and a member of the Communist Party.

Now when I was about 17 my grandfather, who was a ‘Butty-man’ with my father, he retired when he got old, he got the coal dust on his lungs. And father said to me one day he was going to take me in with him as a ‘butty’, so I was a butty. That was all right by me because we paid the men who were working for us and we shared the money out between us afterwards. I used to work it out what the men’s wages were who were working for us. And I used to work it out on paper the night before, on the Thursday night. Well, when we were at work the next day I would go to the main office after we came out of the pit and draw the money out from there. I’d put it down on paper what these men were due to be paid out of the money I had picked up. Whatever was left over I shared between my father and me, that was the butty system.[ 45 ]

Hodding

Hodding was used in the house coal pits to transport coal from the coal face to the dram loaders in a hod which was a large wooden box on skids.[ 46 ] Most of the hodders were teenage boys and in 1928 they were paid about 20p a day. Those that volunteered may have preferred hodding to other jobs such as working on the screens, or ‘road zwippin’ where they would only get 10p. In addition, hodding provided an opportunity to learn the skills of a hewer and the status that involved.

Hodders had to drag the hod along by hand and knees using a chain attached to a leather harness that ran between their legs and over their shoulders. Some of the seams were only about 12 to 18 inches high, so the work often resulted in injuries to their back, knees and private parts.[ 47 ] Fred Warren started work as a hodder at Foxes Bridge Colliery in 1913 and described his first day at work as follows.

Oh, I d’ aim I was 14 or more, just about 14, because we had to go up to the pit in the morning, stand by the cabins and see all the men go down and if there were two butties on there and they hadn’t got nurn a boy, they would come out and look around at you. You were like cattle in a market. They would look at you and if your backside did stick out a bit, they did say “he might be able to do a bit of hodding”.[ 48 ]

Similarly, for Albert Meek who was born in 1898 and started work at Crump Meadow in 1911:

You’d cry all day and you would cry all night. You would get sore shoulders; you would get sore knees. And you would say to your parents “what would you do for my sore knees?” “Put them in the jerry!”[ 49 ]

In 1983, Harry Roberts provided an account of his first day working as a 14 year old hodder for a pair of buttymen at New Fancy, a house coal colliery, in 1928.[ 50 ]

My ‘Butties’ were looking for me and I was looking for them. A voice said, “Bist thy name Roberts?” and I said, “Oy it is”, then another voice said, “we be thy Butties let’s go to work”. The eldest was Car short for Cornelius and his brother was Charlie, this was their introduction.

My memory of the events of 1928- 1930 remain indelible, I still see my two Butties with their blue tinged scars puffing and wheezing to get their breath, the trilby hat of Cornelius, the tattered cap of Charlie, and the voice of one or the other saying, “Come on old Butt we be waiting for thee and thy ‘odd”. There ‘Car’ chiding God because handling extra dirt was losing us money.[ 51 ]

The dangers of making generalisations about the hierarchy of exploitation of the contract system within the Forest coalfield or elsewhere is illustrated here when Harry Roberts expresses some affection towards his old ‘butties’. The difference is status and earnings between the Cornelius and Charlie and that of a skilled day wage hewer were probably marginal. Harry Roberts points out that the brothers were constantly being taken advantage of by the owners of the colliery and work was often held up and earnings lost because of a shortage of drams or timber. In some cases, the management adjusted the price lists so that the rates earned from piece work were only marginally above the statutory minimum day rates, the coal sometimes was rejected because it had too much dirt or small coal in it or mistakes were made in checking the number of drams at the pit head. Harry Roberts remembers:

The Butty system of getting coal was mainly a piece work system, and the two brothers were to be paid just over 18.5p a ton for the winning and loading, the average capacity of each tram being 1.25 tons. …. Sometimes we had an extra day’s pay at the end of the week due to increased tonnage then the job was re-priced, it fell from 18.5p decreasing four times in six months to about 14p a ton for cutting and loading and because of it we could not get our money so the Company was obliged to make it up to the statutory amount.

On Fridays there were arguments at the pay office where men having kept account of their drams sent up during the week found they were short and consequently the tonnage was down, most miners lost two or three like this so the little extra they worked so hard for they didn’t get in spite of the ‘checking’ by the checkweighman, and the miners considered the ‘lost’ tonnage was stolen from them.[ 52 ]

While working for with the brothers Harry Roberts got to know Mr Parker, his son and son in law who were being paid by the cubic yard to drive a new horse road using explosives. Mr Parker occasionally employed an old collier to help him and one day he spoke with Harry Roberts:

“Bist thou the boy ‘oddin ‘fer them Evans’s?” I assured him I was and he replied, “Then thou bist lucky, I done ‘oddin’ when I was thy age fer 6d (2.5p) a day, and 10 ‘owers on’t, and we didn’t ave such a good odd strap as thee, I ad one around the waist with a chain at the back o’nt and it pulled thee spine and crippled some of the boys, and thou’s get paid vower bob (20p) per day fer only 8 hours.” I told him things had improved in the last 50 years.[ 53 ]

Conditions hadn’t improved that much as hodders working he Brazzilly seam at New Fancy sometimes had to work in up to two-foot of water in a three-foot space. Mr Parker’s son worked there for a while and when Harry Roberts returned eighteen months after leaving the pit, he discovered the boy had died of rheumatic fever.[ 54 ] The use of teenage boys to work in these conditions was perhaps the most pernicious aspect of the butty system.

The Full-Time Agents

The most influential person in the FDMA was the full-time paid agent who was responsible for all the main tasks carried out by the union. George Rowlinson was the full-time agent from 1886 to 1918. He worked closely with the checkweighmen and buttymen who dominated the FDMA Executive during his years in office. However, in March 1918 Rowlinson was voted out of office by the FDMA membership and Herbert Booth was elected to take his place.[ 55 ]

During his election campaign, Booth was vocal about his opposition to the butty system. This was based on his experiences campaigning against the butty system while working in his native Nottinghamshire where he ran into conflict with moderates in the Nottingham Miners’ Association who supported the butty system.[ 56 ]

By 1916 the rumblings of dissent were to be heard on every hand. As yet no organisation appeared to fight the evils which corrupted the working life of the miner. Appeals to the Association were of no avail. The Council meetings were still made up of butty delegates and checkweighers, the branch committees were strongholds of the system. The opposition took the form of an unofficial movement.[ 57 ]

Booth had a good understanding of how the butty system worked. He was also aware how the buttymen used a variety of tactics to increase the pace of work such as the use of a monkey butty which was a dayman paid a few extra pence to set the pace of work.

The butty often had little need to set the pace himself, rather it could be set by a monkey butty.[ 58 ]

After arriving in the Forest, Booth started to build up a network of younger day wage miners and encouraged them to get take on roles within the FDMA. He even persuaded the FDMA committee to sponsor a couple of young miners to attend the Central Labour College in London which at the time was effectively a syndicalist training school.[ 59 ] However, during the lockout, the whole mining community had to unite to fight a determined battle against the imposition of huge wage cuts and the possibility of pit closures. The issue of differentials and inequalities among working miners were put on hold.

After coming to terms with the devastating impact of defeat many miners, including some buttymen, in the Forest found themselves working for minimum rates and discontent with the butty system grew. At the beginning of 1922, with the FDMA still in disarray after the lockout, Booth handed in his notice and returned to Nottingham. He got a job as checkweighman at Annesley colliery and found out that the butty system in Nottingham had grown with and “the proportion of daymen to butties was now any number from one to twenty”.[ 60 ] He discovered:

the lodge or branch committees were almost exclusively made up of buttymen’s interests, all the union’s activities bore the impress of their aspirations. Good stalls and office on a branch committee went hand in hand.[ 61 ]

When John Williams was appointed as the new FDMA agent in March 1922, he immediately ran into conflict with some of the older checkweighmen on the FDMA Executive, partly because he was hostile to the butty system. In particular, he was concerned that in some pits there appeared to be a cosy relationship between the buttymen and the managers. He soon built up support within the wider mining community and recruited day men onto the FDMA Executive who started to challenge the use of the butty system. At the same time, nationally the system was coming under criticism by economists like J W F Rowe who wrote in 1923:

It is hardly necessary to point out in detail the iniquities of sub-contracting systems; in coal-mining the difficulty of adequate supervision from the owners’ point of view is obvious, and the butty system saved a lot of trouble. But since the butty’s profits depended very largely, if not entirely, on the amount of drive which he could put into the men, the system involved much bullying, and moral and physical degradation. Moreover, it was most unjust that a man should not get a reward commensurate with his efforts even if those efforts were not given freely, but extorted by force majeure.[ 62 ]

John Williams

Williams was born in 1888 at Kenfig Hill, in the Garw Valley, South Wales. His father worked as a hewer at the International Colliery, Blaengarw. In 1901, at the age of 13, Williams was sent down the pits to work for his father under the contract system. One year later he was involved in a terrible accident. His father had bored a hole with a rammer and inserted explosives. However, at the first shot, the fuse misfired. The regulations stated that it was necessary to wait 24 hours before making a second attempt. However, the hewers, working on piece rates, were under pressure to ignore this rule. As a result, Williams approached the face and was severely burned in an explosion. He was lucky to survive but had to spend six weeks in a bath of linseed oil.[ 63 ]

Williams helped to re-build the FDMA leading the miners through the 1926 Lock Out and the depression of the early 1930s. In this task, he was helped by David Organ who was elected President of the FDMA in 1919 and remained in this role until 1939. Organ started his working life as a hodder at New Fancy but by 1913 was working as a checkweighman at Norchard colliery. He was blacklisted after the 1926 Lock Out but eventually got his old job back at Norchard.[ 64 ]

In an interview in 1961, Williams described the butty system as follows:

It was a vicious and wholly corrupt affair. Under it, one man could exploit several of his mates. It was a paradise for back scratchers, but a wicked hardship for most colliers. The system was simple but very successful for the Coal Owners. One collier would be put in charge of several others. The Buttyman would be paid on a price list while the colliers working for him would only get the District Minimum.[ 65 ]

Campaign Against the Butty System

As a result, resentment against the butty system grew and pit by pit, seam by seam, the system was abandoned.[ 66 ]

Forest miner, Alan Drew, remembers:

Three shifts – one man in charge of each place. All money earned was paid out in the butty man’s name, and then he shared out – they were sub-contractors, taking on the job of getting coal out and hiring men. But it wasn’t the men doing the work who was getting the money; the butty men had the biggest helping. The system wasn’t liked.[ 67 ]

And for another Forest miner:

Well, actually I was only a boy under the butty system……..What was happening, in them days was that you’d get three buttymen, one on each shift, and if you was thick with a manager or an under-manager, they put three boys on with you so that you could get above five bob a day. There were a lot of dirty things going on as well, mind. As it happened, during my period, in my teens then, I was lucky enough to get along with decent blokes, like, and although the amount of my money was about five bob a day, my first wage for six shifts was two-and-eleven per shift and they give I three bob. During my teens, I worked along with blokes and they’d pull me right, so I was all right. Say my money was about five bob a day, I might get seven bob a day, you know. If I done all right, they might give I seven bob a day, something like that……….There were a lot of trouble with this butty system, a lot of trouble, haggling and swarming out with these trucks. I used to get out on a Friday: they’d all get down into little groups, you know, sharing this money out. One butty-man would even try to do his mate, another butty-man, you know. It was a very unfair lot altogether, although I wasn’t mixed up in it really. But it was terribly unfair. It was a lot better when that was abolished.[ 68 ]

Share-Out System

The butty system was gradually replaced by an arrangement where the piece work earnings were, in theory, shared out equally between the men in the team. In the Forest this was called the share-out system (sometimes the all-throw-in system), although there may have been differentials in the bigger teams depending on age and experience and one man was usually responsible for the workplace. At first, boys were often still employed as hodders and trammers and sometimes there was little difference between the two systems. Jesse Hodges (Jnr) remembered how his father campaigned against the butty system at Crump Meadow and the share-out system was introduced:

There was a time when my father helped to break the butty system whereby every man would have an equal share of the money that was earned on the face in the mine. The boy had a fair amount, the hodder and the men shared the residue between them which was a fair share. The men did at Crump Meadow and at most pits, but at Crump Meadow in particular the money was paid out at the Bilson Offices, which today belongs to Roberts’ shop. The wages used to be paid out to the head butty like my father and the men used to come and squat all round down by the offices and in their little groups from each place and these butty men did then bring the money and share out between them. The stall or place was in the butty name and the pay bill was also in his name and then he used to pay them out, share it up and that was how it was.[ 69 ]

Fred Warren described the process of how two colliers would get their own stall or section of seam under the share-out system:

Oh well, the two would be I and Alan, look. We’d be at the top of the pit and there’d be a place a going in a seam look, there were lots of different seams a going and you would go and ask the overman about a start on your own and him would say “Oh yes, we can give you a start on your own” if they thought you were qualified and him would say “We’ll give you three bob a ton to get this”.

And each cart that do come out, you did have a number that was registered on top that your cart had gone by, tonnage, etc. These various places was called headings, we foresters called it the “Dip Yud” and the others was called the “stall”. Probably a couple starting off from new would have a stall, the old colliers would have deep heading and they drove the roads, you know the main headings. That’s how it went on and they did employ a hodder and a filler. The hodder did heave the coal out in the trolleys in the stall because you had to trolley that coal down to the main road look.[ 70 ]

In the 1920s, the first pits to abolish the butty system were the steam coal collieries Princess Royal, Cannop and Waterloo where the owners tended to be more enlightened. They invested in their pits, and they were the most modern in the Forest at the time. The managers recognised the FDMA and were willing to negotiate with the union over pay and conditions.

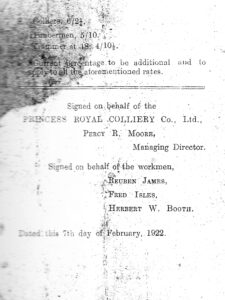

Consequently, the FDMA was able to negotiate independent agreements through collective bargaining which included a detailed price list, day rates for different grades of workers and other issues such as variations on shift pay. The hewers were still paid on tonnage rates, and the piece rates for other work such as timber work and road ripping were set out in the price list. An example of this was the new agreement negotiated by Herbert Booth and Reuben James at Princess Royal colliery in January 1922.

In contrast, the pits owned by Henry Crawshay Company Ltd, Eastern United, Lightmoor and Foxes Bridge, tended to lack investment, continued to operate the butty system and often refused to negotiate with the FDMA. During the 1926 Lockout, the Crawshay’s were able to break the solidarity within the Forest coalfield by attracting a handful of men back in August. The buttymen who returned first would get the best stalls and daymen who returned would get preferential treatment. Men who had inherited their places of work from their fathers could lose them forever. Naturally, this led to bitterness and recrimination and no wonder there were cases of threats, intimidation and violence against those returning to work.

After being out on strike for four months, the checkweighmen joined the general drift back to work. As ‘employees’ of the buttymen it was unlikely that they would have taken this action without their knowledge and encouragement. Consequently, on 4 October, Daniel James and Harry Hale, checkweighmen at Lightmoor were expelled from the FDMA for returning to work.[ 71 ] On 17 November, Enos Taylor and Brain, the checkweighmen at Foxes Bridge were also expelled.[ 72 ]

Taylor was a longstanding and loyal FDMA Executive members and his expulsion reflected the state of crisis within the FDMA, who still had a hardcore of members determined to stick it out to the end. Many of these men, including some buttymen and checkweighmen, were later blacklisted by the owners. In his 1961 statement, Williams acknowledged:

this was the beginning of the end of the strike in the Forest of Dean. Nearly every day now I was called to most of the collieries to deal with men returning to work. The workmen had been out of work for over four months. They had not received a penny strike pay out of our funds. We had no funds. The only payment received by the workmen of this district was one payment out of what was described as “Russian Money”.

By the end of five months, all the workmen in two collieries had gone back to work and a considerable number at the other collieries as well. Some of the workmen had no food to take to work and were without any until pay-day. I managed to keep two large collieries idle to the end of the strike. The situation was a nightmare for me, and when it was all over, I had to start from the beginning again to organise the district.[ 73 ]

Enos Taylor and the other checkweighmen were subsequently reinstated into the FDMA. However, after the 1926 lockout ended, Williams continued to campaign against the butty system locally and nationally. Herbert Booth was also having severe problems in Nottingham because the butty system had become more widespread and associated with the rise of company unionism which would plague the coalfield right up to the 1980s.[ 74 ] In 1926, individual buttymen in Nottingham continued to employ a large number of workers and they were instrumental in undermining the strike very early on because, on returning to work, they could still earn good money.[ 75 ]

In the Forest, the influence of the FDMA was severely diminished after 1926 and the dangers of the buttymen or teams of hewers competing for contracts was highlighted in early 1930 when Williams discovered a price list had been agreed at Norchard colliery without the agreement of the FDMA.[ 76 ]

Hours of Work

One of the main campaigns of the MFGB and FDMA after 1926 was to reduce hours of work to reduce unemployment and prevent overproduction. However, in 1930, the introduction of legislation to reduce hours of work in mines to seven-and-a-half-hours became a thorny problem in areas where the butty system operated. The buttymen were concerned about loss of earnings and were keen to get as much coal weighed in at the pit head before the end of the shift and often put pressure on the trammers to work extra hours in contravention of the regulations. Clearly, this suited the mine owners, but not union men like Williams and Booth who were concerned about their unemployed members. In some pits in Nottingham the buttymen had by now established a company union in opposition to the Nottingham Miners’ Association.[ 77 ]

As a result, the first resolution presented to the MFGB conference in August 1930 by Booth, proposed that:

The Miners’ Federation of Great Britain’ Committee take the necessary steps to make the butty system illegal.[ 78 ]

Booth described the system as one that created a cleavage between the men, not only in the pits but in social life. Williams backed Booth up and said:

only districts that had experienced the system had any idea what an abominable thing it was. Not only did it corrupt the relation of men with employers, but it corrupted the relations of workmen with one another. As a rule, a butty was a man who was a sort of boss without the status of one. He was a driver and a forcer and a man who often did little work himself. It was usually, as a rule, to find that where the system worked there was a low membership. At one colliery where the system works in my district, the average membership is less than 50 per cent. In a neighbouring colliery a mile away, where the system does not work, the membership, over the same period, is in the neighbourhood of 75 per cent.[ 79 ]

The resolution was carried unanimously. The colliery referred to by Williams with an average membership of less than 50 per cent was probably Eastern United where butty system was still being used up to 1938. By this time the steam coal pits, excluding Eastern United, and most of the house coal pits had gradually changed over to a system where the labourers, trammers, and hodders were paid by directly by the colliery owner and the colliers in the team shared the money out amongst themselves.

Tramming Dispute

However, there were still anomalies leading to disputes between the owners and the colliers over who was responsible for certain jobs as this could impact on piece-rate earnings. At Waterloo, a steam coal colliery, the colliers had traditionally done their own tramming. However, at the beginning of November 1935, the men gave notice to the management that they no longer would do this. As a result, on Saturday 9 November, seven men were dismissed. On Monday morning 11 November, the seven men were turned away and as a result, nearly the whole workforce of 650 men walked out on strike. A mass meeting was addressed by Williams and it was resolved that the strike would continue until the seven men were reinstated and the company agreed to provide the labour for tramming.[ 80 ]

The men returned to work on the following Thursday on condition the employers took no action in the courts against any workmen concerning the strike and undertook that there shall be no victimisation. It was agreed that a scheme would be mutually discussed with the view to end tramming by colliers and that such scheme to be in operation within three weeks. The wage rates of trammers would be discussed at the same time.[ 81 ]

Following this on Monday 18 November, forty miners received a notice to terminate their contracts based on a reduction in the number of seams available to be worked. As a result, the workmen walked out on another lightning strike. John Williams organised a mass meeting of the men in Cinderford. The men were transported to Cinderford in buses from all around the district, and the meeting lasted about three or four hours. As a result, Williams sent a message to Joseph Hale, Secretary and Director of Lydney and Crump Meadow Collieries Ltd. asking for certain assurances.[ 82 ]

Hale agreed that the forty men would be replaced in other parts of the pit, half of them immediately and the remainder as soon as they could be absorbed. An assurance was also given that no men would be prosecuted in connection with the strike and victimisation would not be countenanced by the company. It was agreed that the tramming dispute itself would be relegated to the Conciliation Board if no agreement could be reached and the men would return to work the following Monday.[ 83 ] In the end, the Hale agreed to take responsibility for paying the trammers.

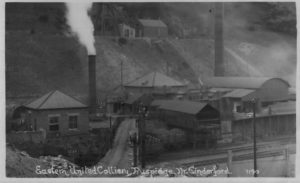

Eastern United Colliery

In the 1930s Eastern United was producing about 330,000 tons of coal annually mainly steam coal but some for household use. The principal seam was the Coleford High Delf which produced steam coal and was approximately 5 foot thick. The workforce included 750 men underground and 120 above ground. The pit was owned by Henry Crawshay & Co. Ltd., which also owned Lightmoor Colliery where the butty system had been abandoned. The company was also in the process of developing a new pit at Northern United.

The Managing Director was Frank Washbourn and he was assisted by David Lang who had been a manager at the Parkend collieries. Lang and Washbourn were the only directors who knew anything about mining. The manager Ted Oakley was appointed in January 1926. He had worked as under manager at Lightmoor. The other Directors were descendants of Henry Crawshay who had invested heavily in mine and ironworks in the Forest of Dean from the mid-nineteenth century onwards.[ 84 ]

They generally spent their time hunting and fishing or on genteel leisure pursuits such as studying nature, painting landscapes and writing poetry. In 1961, John Williams said that at Eastern United:

Not more than a dozen workmen were in the Union at this colliery. No workman dared mention the union at this colliery. Most of the Buttymen were undercover agents for the management, and the Managing Director was as tough as they make them.[ 85 ]

One of the workers at Eastern, Wallace Jones, was keen to bring the system to an end. Jones had been elected onto the pit committee, which was made up of representatives of workmen from different jobs and parts of the pit. In particular, Jones had built up support among the day men who worked for the buttymen. He was also the FDMA Executive member for Eastern United.

Wallace Jones

Wallace Jones was born in Cinderford in March 1894, the son of a grocer. He left school at the age of aged thirteen to become an apprentice baker. The 1911 census lists him as working as a woodman on the Crown Estate in the Forest of Dean. Soon after he moved to Aberdare to work in one of the Powell Duffryn collieries.[ 86 ]

In 1914, at the start of the First World War, Jones joined the Royal Welsh Fusiliers and served with them in France and Belgium. In December 1916, he was buried by a shell explosion and was the only one to survive among a group of six other men. He was invalided home to England. He was then was billeted to the Labour Corp where he was promoted to the rank of corporal.[ 87 ]

He was discharged from the army on 13 May 1919. He then worked for a short time in a local timber yard before joining the Eastern United Colliery where he remained for 30 years in roles that included trammer, road repairer, face worker and then for sixteen years as a master haulier.[ 88 ] In the late 1920s, as was the case for many of the older and more experienced colliers, Jones worked as a buttyman.

Mass Meeting

In November 1937, Jones and Williams decided to bring the butty system at Eastern United to an end and so met to discuss tactics. At the end of November 1937, they called a public meeting at Cinderford Miners’ Welfare Hall and to their surprise, most of the Eastern United workers, including the buttymen, turned up.[ 89 ] David Organ president of the FDMA chaired the meeting. Williams explained to the men the reason for calling the meeting:

I am told there is dissatisfaction at Eastern United Colliery that is extensive and very deep. There must be a cause for it. I am told that one of the causes is the existence of the butty system, and it is significant that the butty men themselves are against it. Many years ago, the system was at least popular among butty men, because they earned big money at the expense, of course, of those who worked for them. Now things have changed, and a process of cutting has been going on so that butty men are getting money that they could earn on a wage basis. They know that under a share-up system they would get more than they are getting at present. I submit that under a share-up system, workers at the coal face ought to be earning between 14s and 16s a day, and in some places, they ought to be earning up to 18s a day. All the men would receive decent wages, and output would undoubtedly increase. I dare say some of you might be unwilling to part with such an old friend as the butty system, but when you look at the question straight, it will be far happier for you if it goes forever. Is it reasonable to expect a man on wages to extend himself as he would if he were paid on a share-up basis, and so benefiting from his own increased efforts?[ 90 ]

The meeting agreed that the miners employed at Eastern United Colliery would decide by ballot whether the butty system shall be abolished or not. Jones also informed the meeting of the details of the price lists in operation at Cannop and Princess Royal Collieries and set out the rates paid for different classes of work. There was not one dissenting vote when the resolution to organise a ballot at Eastern United was presented to the meeting. It was also decided to authorise negotiations for rates of pay for dead work on the basis of the rates paid at Cannop Colliery.[ 91 ]

Dilly-dally methods

The ballot resulted in 336 votes in favour of abolition and 46 for retention. A miners’ deputation supported by Williams then met the owners just before Christmas to discuss the results of the ballot. However, the owners put off making a response until after Christmas and then used a series of delaying tactics to obstruct the implementation of the men’s demands. In response, Jones and the pit committee at Eastern United asked the FDMA Executive to consider strike action because of the “dilly-dallying methods adopted by the company over this issue.”[ 92 ]

Consequently, a miners’ meeting was held at the Sunday 23 January in St Annals Institute, Cinderford where Williams gave an address expressing his frustration at the delaying tactics of the management. Since the butty system question had arisen, another dispute occurred at the colliery, concerning fitters. The fitters at the colliery were being asked to do work other than the work properly assigned to them.[ 93 ] As a result, the tension between management and workers at the pit was increasing. In due course, another meeting was arranged with the Directors. However, this time the Directors insisted they would only accept the results of an independent ballot.[ 94 ]

The FDMA Executive agreed to this demand. However, the Directors continued to be obstructive and tried to delay the organisation of an independent ballot. In addition, they sacked Jones and two other workmen. As a result, on Monday 21 February, the Executive Committee of the FDMA met, and it was decided that the workmen at the colliery should tender notice on Monday 28 February with the view to take strike action the following week. In the meantime, it was agreed that Williams would continue to attempt to settle the dispute peacefully.[ 95 ]. Williams told a Gloucester Journal reporter that two main reasons influenced the Executive in its decision to approve a stoppage at the colliery:

(1) The refusal of the Company to carry out an undertaking mutually agreed upon between the workmen’s representative and the Company, namely, that the results of the independent ballot should form the basis of the negotiations for the abolition of the butty system.

(2) The dismissal of Jones, the FDMA’s representative at the colliery, and two other workmen.

Coal Owners’ Association

Meanwhile, in addition to the three men dismissed, three more had been given notice. Negotiations continued and Organ, Williams and Jones worked day and night to resolve the dispute. In an attempt to get a settlement, the talks now involved representatives of the Forest of Dean Coalowners Association which included the managing Directors from Cannop and Princess Royal. In the end, the threat of strike action resulted in the company making a new offer which included the abolition of the butty system subject to a few minor conditions.[ 96 ]

However, the offer included a clause which stated that the three men under notice and the three men who received notice could no longer be employed at Eastern United. The Company said they would find work for them at another of their pits in the Forest but with no guarantee of the type of work. This was not acceptable to the FDMA and representation was made for their retention at Eastern United in their old jobs. Williams reported to the Gloucester Journal:

We were worried about these terms, and we determined to make further efforts to get them revised. A further meeting was held with the owners on Thursday 3 March when we made certain suggestions. I must say that a very strained atmosphere prevailed at this meeting. When the Directors had considered our suggestions, during which we had retired, we came back to an attitude of take it or leave it. With regard to three men, it was stated that one could have a job at Lightmoor, that another, Wallace Jones, could be given a job at the coal-face, and that the other should also be given a job at the coal-face. The men were not used to the work which was proposed for them, and I knew the offers would be unacceptable.[ 97 ]

This meeting was followed by a further meeting of the FDMA Executive and pit committee, at which it was decided the terms could not be accepted:

I asked the Executive to give me the authority to write to the company the next morning to tell them we were going to take strike action, not slyly but openly, so that it could be said we were doing everything above board.[ 98 ]

Victory

The negotiations continued until Saturday 5 March when Williams sent a final letter to Washbourn and Lang. There seemed to be little hope of averting a stoppage. However, the outcome of William’s letter resulted in a meeting early on Saturday evening between members of the FDMA Executive, the pit committee, Williams and the Directors of Eastern United. At this meeting, the owners made a new offer regarding the dismissed men and the employment offered to the men was deemed to be reasonable. In his November 1961 statement, Williams paid tribute to Jones’ contribution to the success of the campaign:

As a result of his activities in organising opposition to the Butty System, he was sacked. I got him work at another colliery belonging to the same company, and in the meantime, he was appointed Checkweigher at his colliery, and throughout he gave signal service to the union of this district. The credit for this success belongs mainly to Mr Wallace Jones.[ 99 ]

Williams explained the result of the various negotiations between the FDMA and the Company at a mass meeting at the Miners’ Welfare Hall on the evening of Saturday 5 March. The Hall was filled to capacity, and hundreds of miners sat or stood for three hours while Williams detailed the negotiations with the Company. The news that the owners had revised their attitude, and that the significant points in the dispute which had been settled were received with cheers[ 100 ]. In his November 1961 statement Williams explained:

The colliery was like a prison before. Things changed drastically, after this, and the membership increased rapidly, and I was able to improve the conditions under which the men worked. For example, the workmen had to work in bad air. There was hardly enough air to burn a candle. One candle would last a whole shift. This state of affairs shortened the life of miners tremendously. I was glad to get the chance to put this right. I brought the terms of the Mines Act to bear on the situation, and soon we got the foul air removed from all the coal faces.[ 101 ]

Individual Wage Packets

This was not quite the end of the story because the social relationships based on privilege and inequality continued in relation to the allocation of places to work. Miners could easily be victimised by given places to work on poor seams and wet conditions where less money could be earned under the piece-rate system. It was in under these circumstances that it was important to be in the FDMA to provide protection from the management and to negotiate the price lists according to the conditions.

During the Second World War, the FDMA and Williams fully supported Forest miners when they took strike action over issues of relating to pay and conditions. However, in January 1942, Williams had to deal with the threat of industrial action at Eastern United over the issue of individual pay packets. The dispute had its roots in the butty system.

In most cases of teams working on piece work, one person was still often responsible for the stall or section of seam and had continued to collect a joint wage packet for the team with a view to sharing it out on an equitable basis. The problem was that it was unclear how much money any individual was being paid or whether the butty system had continued in some form or another with the money not being shared out equally.[ 102 ]

In addition, this arrangement caused problems with income tax since there was no record of actual earnings by any individual miner working in the team. Consequently, some members of the team may have been paying more or less tax than they should. Also, injury compensation was based on earnings and if the company had no record of actual earnings then benefit would be difficult to calculate.

As a result, on 31 December 1941, in response to requests from its members mainly in the West Dean pits, the FDMA presented a proposal to the colliery owners that in future all the workmen should be given a separate wage packet setting out their earnings and deductions individually. The owners agreed but on condition that the extra clerical work would mean payday being put back by two days. On 16 January 1942, some men at Northern United and Eastern complained about the new arrangement and at Eastern, this led to a threat of strike action. Williams was appalled and issued a statement which included:

Fellow Workmen. For some time now an agitation has been on foot among you and there has been some talk of going on strike, and a lot of talk about taking a ballot on the settlement reached between the coal owners and the Miners’ Executive on the miners’ demand that each workman should be given a separate pay packet. I am ashamed that there are miners to be found who are so short-sighted, and in some cases so mean, as to associate themselves with this stupid agitation[ 103 ]

The increasing authority of the FDMA meant that Williams was able to prevent an unnecessary and reactionary strike and from now all the workmen would receive individual wage packets. In February 1942, Williams negotiated an agreement with the owners that all miners would be required to become members of the FDMA.

Conclusion

It would be difficult to fully comprehend the history of trade unionism in the Forest of Dean coalfield without an understanding of the butty system. This also applies to other coalfields yet in the classic labour histories of the British coal mining industry the butty or contract system hardly gets a mention. This is the case of R Page Arnot’s three-volume study of the history of the Miners’ Federation of Great Britain.

The butty system in the Forest survived for over a century, not only because it suited the colliery owners, but because its persistence depended on its acceptance by the mining community. The buttyman epitomised the ideal of an independent collier which had its roots in the free mining tradition in the Forest of Dean. The amount of money a buttyman could earn was dependent on his skill and effort and his ability to extract labour from his workforce. As small working masters, the buttymen attempted to reclaim the authority, dignity and respect which lay at the heart of their heritage as free miners. The ambition of many young skilled colliers was to be allocated their own ‘place’ and this was understood as a natural career progression after completing their ‘apprenticeship’ with a buttyman.

Mining was highly skilled and based almost exclusively on knowledge gained through extensive experience of coal extraction in a range of geological conditions. Albert Meek explained:

Then you got rock road to drive and one thing and another; timbering – we were complete colliers we used to do the shot firing. They’ve got shot firing separate these days. We used to do all the timbering and we used to do everything that you could call a collier. You had to be complete colliers at that time.[ 104 ]

The buttymen were usually respected members of their community with the status and authority of highly skilled artisans. Some miners, in particular the buttymen, owned more than one house and maybe a pub or a shop and some land, while many daymen could be tenants or lodgers with no other means of support. In fact, there was a long tradition of buttymen owning pubs in the Forest. Harry Barton was born in King Head Hotel in Cinderford which was owned by for about six years his father who worked as a buttyman at Lightmoor colliery.

As a result, there was also a hierarchy of wealth and status among the miners themselves, exacerbated by the differentials in earnings at work and, there were significant differences in housing conditions and levels of poverty within the community. Winifred Foley in her account of a 1920s childhood in the Forest of Dean recalls:

The women from the better-off end of the village and a sprinkling of the husbands were regular chapel-goers. Not so the other end. All too often the poorer women ‘hadn’t a rag to their backs good enough for chapel!’[ 105 ]

However, when it came to big industrial disputes which threatened the whole mining community, the buttymen and the daymen usually stuck together. The Forest miners remained solid throughout the three months 1921 lockout, on the other hand, in 1926 the strike was weakened by the action of some of the buttymen. However, after the defeats of 1921 and 1926, unlike Nottingham, the rates of pay for all miners in the Forest, including the buttymen were reduced to minimum rates or just above, and this continued into the 1930s and was one of the reasons that led to the demise of the butty system.

It is probable that many Forest buttymen treated their workers well and there was a strong sense of loyalty and solidarity within the teams. After all, a skilled collier would not work for a buttyman who treated him badly. At the same time, it was likely that some buttymen were bullies and exploited their employees and it was the abuse of teenage boys that was the most brutal aspect of the system. In the end, it was the system itself that became unpopular and it was ex-buttymen such as Jesse Hodges and Wallace Jones with the support of John Williams who helped to finally rid the Forest of a system that only benefitted the colliery owners and their shareholders.

However, the differentials remained and hewing teams, working on piece rates, continued to earn significantly different rates from each other and both between districts and pits. This remained the case until the Forest collieries closed in the 1960s. In 1983, Harry Roberts returned to the Forest and reminded us of a bygone age of 1928 when, at the age of 14, he arose at 5 am, cycled several miles to the pit to queue up to get a place in the cage to descend into the pit ready to go to work for his buttymen:

The Banks Man gave the signal to the operator in the engine house and the downward journey began, soon water began to pour out of the sides of the shaft, everyone got very wet as there was no roof to the cage, soon a fairly large tunnel came into view it had whitewashed walls, and electric lights showed up the well made brickwork. Men were sitting on their heels each side of the tunnel, they called it quatting they did not sound the letter s, and men and boys were searching for the men they would be working with. The names of them seemed to belong to another age, there were Ezekia (Kia), Zackaria (Zac), Corneilias (Car) and Emmanual (Mann).

“Bist thou ready for work old Butty?.” “Oy I be”. “Well let’s goo then bring the bwoy along”. ” I be agwain to get the blades vram the blacksmith oust”[ 106 ]

There would be a long walk to the coal face, and there would be water to walk through and air doors to open and shut, all the men in the mine were still wet from the journey down the shaft … The two men and the boy now ready for work crawled on hands and knees to the coal face the distance depending on how far the coal face had moved forward due to the amount of coal extracted.

Postscript

The sub-contract system is still prevalent in many industries in Britain today and provides an effective way for large companies to manage their workforce, extract labour value and weaken trade unionism. A building site today has an uncanny resemblance to a Forest of Dean colliery in the 1920s with small teams of workers operating independently, competing for contracts and undermining solidarity. A form of the butty system still operates in agriculture and food processing where migrant workers are exploited by an officially sanctioned system which uses gangmasters to supply labour. Delivery drivers are now often now self-employed and earning less than the minimum wage. Daywork, sub-contracting, self-employment, zero hour contracts, minimum wages and the use of agencies and umbrella companies are the consequences of a never ending attempt by capital to reduce the cost of labour.

Barry Johnson (1931 – 2020)

It was with sadness that I recently found out about the death of Barry Johnson. Several of years ago I bought a copy of Who Dips in the Tin from the Nottinghamshire and Derbyshire Labour History Society and after it arrived in the post, I discovered he had signed it for me with best wishes. His book is excellent and highly recommended and has been a great help to me writing this article. This is from the Orgreave Truth and Justice Campaign.